Plantrooms, Shafts, Corridors Modules

Specialized modular design services for plantrooms, shafts, and corridors that enhance efficiency, coordination, and buildability across complex projects.

Overview

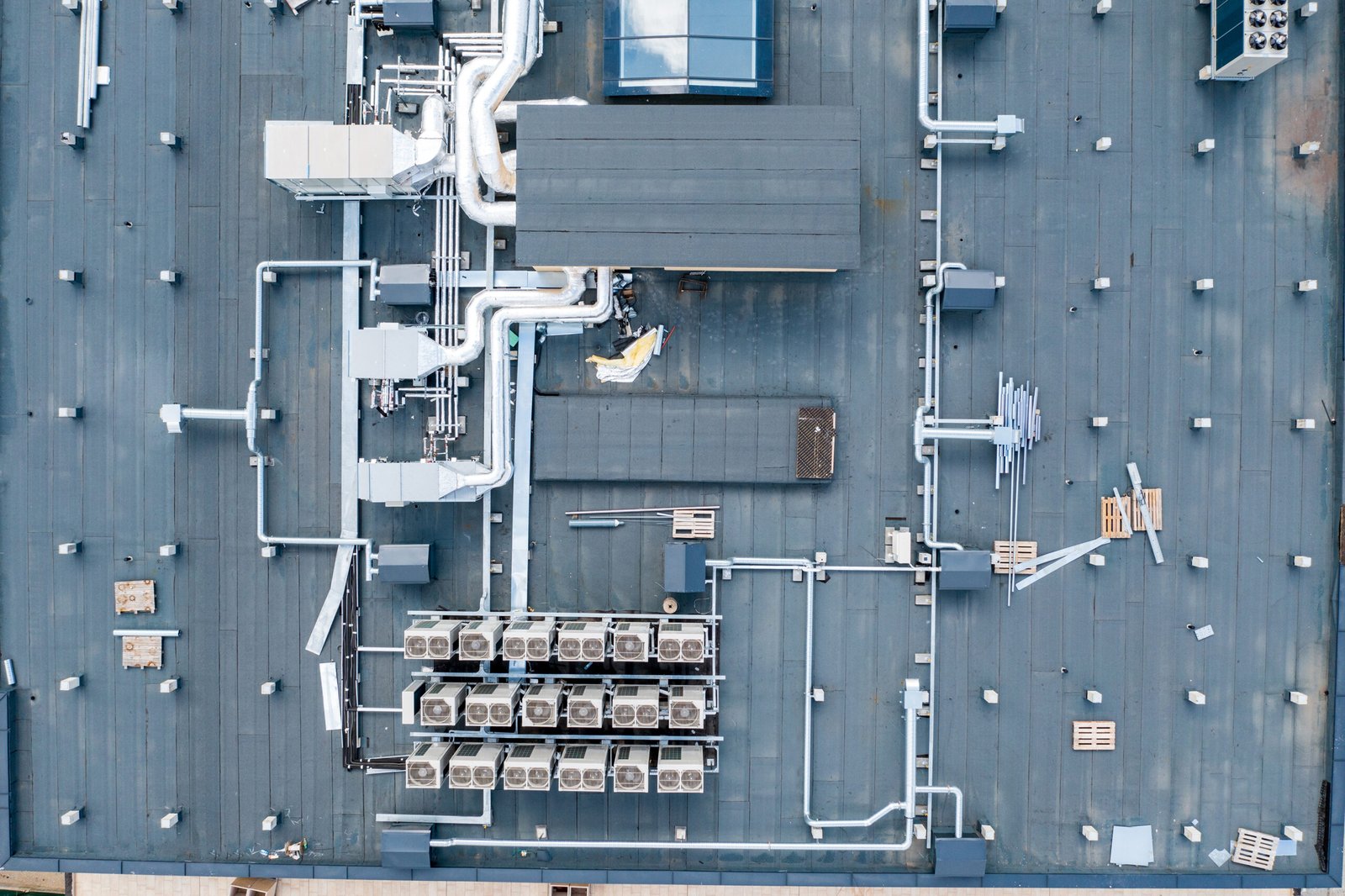

Plantrooms, shafts, and corridor modules are some of the most critical yet challenging areas in construction projects. They involve dense integration of mechanical, electrical, plumbing, and fire protection systems within limited spaces. At Nur Engineering, we specialize in delivering modular designs that optimize these spaces for efficiency and accessibility. Our approach ensures that all services fit seamlessly without clashes, creating layouts that not only meet technical requirements but also simplify installation, inspection, and long-term maintenance. With our expertise, clients achieve smoother workflows, reduced risks, and more reliable project outcomes.

Optimized Space Utilization

Space within plantrooms, shafts, and corridors is often limited, yet it must accommodate a variety of essential systems. Our team carefully designs these areas to maximize space efficiency without compromising safety or performance. By using precise layouts and modular coordination, we help projects avoid congestion and ensure that all services remain accessible for future maintenance. This creates a balance between practicality and efficiency, making these critical spaces more manageable throughout the project lifecycle.

Enhanced Coordination Across Trades

These areas typically involve multiple trades working within the same confined spaces, which can lead to conflicts if not properly coordinated. We provide detailed modular layouts that allow HVAC, plumbing, electrical, and fire protection systems to coexist seamlessly. This proactive approach reduces on-site clashes, minimizes rework, and helps contractors complete installations more smoothly and on schedule. Effective coordination not only improves productivity but also reduces costs by preventing errors during execution.

Prefabrication & Modular Support

By leveraging modular design, our services allow components for plantrooms, shafts, and corridors to be prefabricated off-site. This approach reduces on-site labor, speeds up construction, and increases overall safety by minimizing work in confined or high-risk areas. Prefabrication also ensures higher accuracy in installation, as each module is manufactured under controlled conditions. The result is faster project delivery with fewer disruptions and improved overall quality.

Why Choose Our Plantroom, Shaft & Corridor Module Services

At Nur Engineering, we understand that these spaces form the backbone of any building’s functionality. Our expertise in modular design and coordination ensures that plantrooms, shafts, and corridors are not just functional but also efficient, safe, and long-lasting. We use advanced tools and proven methodologies to deliver layouts that meet client needs while exceeding industry standards. By choosing us, you gain a partner committed to reducing complexity, improving efficiency, and delivering reliable results for your most demanding spaces.

Frequently Asked

How can we help?

They house critical MEP systems that support a building’s overall functionality and safety.

It ensures efficient layouts, reduces clashes, and allows for prefabrication, saving time and cost.

Yes, our services cater to residential, commercial, and industrial projects of all scales.

Absolutely. We ensure all designs meet local regulations and international best practices.

It allows modules to be built off-site with precision, speeding up on-site installation and improving quality.

Need more help?

Feel free to contact us for more information

We are always ready to assist you with your queries regarding tender documentation and project requirements. Whether you need clarification about our process, want to discuss a specific project, or simply require guidance on preparing a strong bid, our team is here to help.

Ready to Take the Next Step?

Whether you need precise estimates, detailed BIM models, or expert consultancy, our team is here to support your project from start to finish.